Discriminating Roasters Across the U.S. Depend on Family-Owned Business

As autumn arrives, Anthem Coffee Imports is heading into their busiest season of the year and working harder than ever. Trucks are streaming in and out, unloading raw beans for sorting and grading, and then hauling them away to roasters all over the country.

“The fourth quarter is huge. Cold weather is a hot time for coffee,” says Anthem Coffee Imports CEO Jon Hanson, walking along towering walls of bulging bags. “It’s especially popular this time of year. Everyone wants it. That never changes.”

Anthem Coffee Imports, Martin City

Anthem keeps a pretty low profile on Wyandotte Street. There’s not much time to poke your head out and look around the neighborhood when you’re managing an endless flow of beans from multiple countries on multiple continents. It’s an extraordinary effort from a surprisingly small team of about a dozen employees. Stand back and watch, and you’ll wonder how they get it all done. Hanson describes complex, interrelated work that’s been elevated to a high art.

“We’re successful because each of us is unique in that we can wear many hats. We buy, sell, and participate in the whole process together. That’s what makes it an especially great experience at Anthem. Everybody knows the business so well. We share the same values. We do more and we’re always thinking about how to do it better.”

(Left to right) Colton Hanson, George Ramirez, Jon Hanson, Jacob Burlin, Martin Pierce and Russell Thorpe were on the clock when we toured Anthem Coffee Imports.

Getting beans of any kind from as far away as Brazil all the way to Wyandotte Street seems like a herculean effort. But these beans are especially valuable and even harder to turn around. They’re the cream of crops across Southeast Asia, Sub-Saharan Africa, and beyond. Anthem finds them, charts their course to Martin City, and then sells them to artisan roasters who want to be proud of the entire supply chain.

“We don’t brew coffee or sell retail. Our customers are mainly ultra-premium roasters,” says Hanson, sifting a handful of raw, green beans through his fingers. “They want anywhere from about five to thirty bags of exceptional beans a month, and then they use roasting techniques to make it all even better. They’re very serious. They want to make great coffee and be able to brag about the whole story from the farm to the cup.”

CEO Jon Hanson says Anthem Coffee Imports specializes in high quality, raw coffee beans. Roaster customers take it from there.

A delicious scent in the air is your first hint that this business is focused on quality, from the beans to the expertise and relationships that power a rich tradition. Mass market beans meeting only minimum standards are a world away from what’s passing through Anthem’s warehouse in Martin City. Even a novice can tell these beans are special. Spend a little time with employees, and you soon realize they’re special too.

“We’re local, family owned, and fully committed. All of us. We work very closely together and we’re in it because we love it. We work very fast and we’re always comparing notes about our product, the people we connect with, and changes in the market. This is an effort that’s taken years of refinement, and we’re very proud of the results.”

(Left to right) Martin Pierce, Jeff Hanson Sr., Jon Hanson, Brian Phillips, George Ramirez, Jacob Burlin, Russell Thorpe, Jeff Sanoubane and Daniel Schildhorn. Click here for more about the whole Anthem team.

Explorers of New and Old Worlds

Coffee begins as a flower that blooms into something resembling a cherry. That’s right, it’s a fruit. Remove the squishy exterior and inside you’ll find seeds that become the ‘beans’ that make the coffee world go round. “Nature’s flavors plus caffeine. That’s our game, right there,” says Hanson. “That’s what it’s all about.”

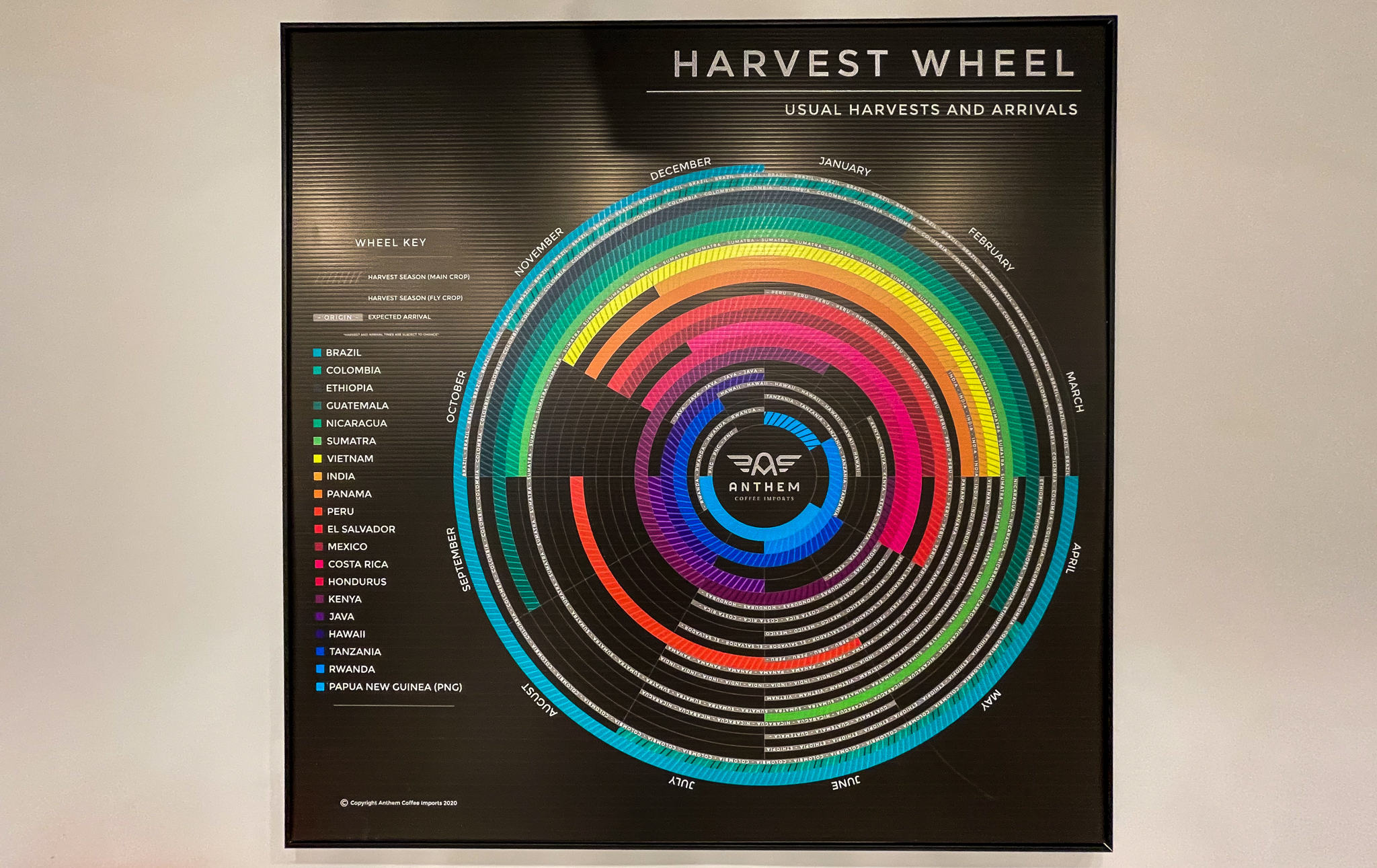

Timing is everything in the coffee business. A coffee plant can take as long as five years to produce its first cherries. Many factors influence the crop, ranging from elevation and soil to weather patterns and growing techniques. Hanson points to a poster on the wall detailing the harvest schedule for growing regions worldwide. It’s a mind-boggling image, but you can tell he knows it like the back of his hand. He’s also got an eye on futures markets where coffee contracts and stocks bounce around like a caffeine buzz, and give him snapshots of supply and demand.

“Importing is a highly specialized part of the supply chain. It requires your full attention and you have to know what you’re doing,” says Hanson with a smile as we marvel at all the data he juggles. “Sometimes a roaster will think they can take on our role, but many soon realize it’s just too overwhelming in addition to their core work, and they quickly get out.”

Getting your hands on the right beans involves a lot of international travel. Frequent flyer miles spin like slot machines as Hanson and his team explore countrysides in far away places. There are no standard ways of connecting with producers and farmers. You have to navigate logistical, political, and even cultural idiosyncrasies.

“You’re cultivating relationships. You’re getting to know people and drawing on your own instincts to figure out who you can trust to partner with you to work through a complicated system of getting beans from the field to our warehouse. These people want to know you too, develop a good relationship, and maintain it.”

In more isolated, rural areas, Hanson says personal relationships become particularly important. “Oh it gets complicated. Sometimes you’re talking to different people speaking in different dialects, trying to not only understand each other, but also forge agreements.”

“We’re privileged to work with the best coffee producers, agronomists, and exporters all over the world,” says 20-year sourcing and sales veteran, Brian Phillips. “We’re committed to championing their interests in our markets, and we make a priority of sharing the impact they make on our business and our customers.”

Brian Phillips of Anthem Coffee Imports on a 2022 trip to Brazil to evaluate beans from over 35 farms.

Harvested beans inside drying beds in Fazenda do Condado, Brazil. Photo courtesy of Anthem Coffee Imports

After an export deal is struck, attention turns to shipping. Who will make it happen and how will it work? And planning must include strategies for dealing with surprises. Anthem buying and sales pro Daniel Schildhorn can tell you stories. “Sometimes you’ve got cargo ships fighting off pirates. Other times there are bait and switch risks. Ensuring secure passage can be a big challenge involving trucks, boats, and trains.”

Transporting valuable beans from distant lands to Martin City comes with many risks.

Masters of Quality Control

Anthem Coffee Imports needs to know specifically what they’re buying before they make a purchase and give a supplier permission to ship. They require samples ahead of each shipment to make sure they’re getting what they’re promised, and once it arrives, another key part of their work heats up.

“Quality Control, that’s our thing,” says Russell Thorpe, Anthem’s certified Quality Control expert. Just about everyone at the company helps evaluate coffee beans, but Thorpe is the lead when it comes to making sure beans meet specifications and are rated properly to enable roaster customers to make buying choices.

Thorpe puts raw beans to the test in every way possible, starting with precise measurements followed by the identification of appearances, scents, and tastes. He analyzes all the stuff that makes coffee so good. Talk about a labor of love. “Yeah, it’s a dream job,” says Thorpe, preparing for another round of testing in the Cupping Laboratory. “I’ve been doing it for about five years and I never get tired of it.”

Russell Thorpe is a certified Quality Control expert at Anthem Coffee Imports.

‘Cupping’ is at the center of Thorpe’s work. Simply put, the process involves grinding beans, brewing, tasting, and then grading the quality. He is obsessive in the way he handles every step. The way he nosedives into cups filled with freshly ground beans, sharply slurps from tasting spoons, and quickly scribbles down notes like ‘fruity, floral and nutty’ before each fleeting experience fades. “You want to take time to think about it, but not too much time or you’ll overthink it and that threatens your accuracy.”

“Descriptions of the character of the beans we sell are critical to our roaster customers,“ explains Thorpe, urgently moving from cup to cup. “They want to know exactly what they’re getting. We also give each batch a score on a scale to 100, and we only offer beans that score near the top.”

Thorpe is all business during a cupping session. Precisely timed brewing, tasting, and scoring is the foundation of the quality control service at the heart of Anthem’s reputation in elite coffee circles. Roasters know Anthem specializes in small batches of the finest beans, and every batch description is as reliable as Thorpe’s mastery of sensory skills. “Smell that? Now go back to the other one,” he says, walking us through cupping. “It’s not quite blueberry. It’s more apricot. Right?”

Of course, we had to ask about his favorite. “Well, that depends on the day, really. But If I had to choose one, it might be a batch that came from Yemen. It tasted like buttercream vanilla frosting. No kidding.”

Russell Thorpe and Daniel Schildhorn in the Cupping Laboratory at Anthem Coffee Imports

A Heritage-Brewed Brand Settles in Martin City

You can trace the roots of Anthem Coffee Imports back to a time and place that starts the story exactly right. CEO Jon Hanson is quick to credit his Uncle Vaughn. “My Uncle was the head coffee buyer at Folgers for a long time. He passed his knowledge of sourcing coffees from around the world to me and my brother, Jeff, when we started our importing business. Our wives, Missy and Earlene, eventually joined the company, too.”

The Hanson brothers got sick of dealing with third party warehouse businesses that didn’t understand the sensitivities around coffee bean packaging and handling, so they moved into their own warehouse space in Martin City in 2018. They liked it so much they eventually bought the building from Peterson Manufacturing. “We wanted to be in a position to control quality ourselves, and the warehouse on Wyandotte Street allows us to do that. Very few importers have their own warehouse.”

Cleaning up and clearing out a former manufacturing space was a huge undertaking. They brought on Logistics Manager Jeff Sanoubane and Warehouse Manager Martin Pierce to coordinate the flow and storage of inventory, which is no small achievement considering more than 80,000 pounds of beans can move through the facility on an average week. “Storage, palletization, and re-bagging are all part of what we do and we can’t miss a beat,” Pierce told us. “Shipping coffee is a whole other science, and organization is everything.”

Thorpe, Hanson, and Schildhorn catch up with Warehouse Manager Martin Pierce.

The team is now building out an office area to include a roasting education space for helping customers refine their craft, and a colorful lobby display detailing the company’s history. Combine those features with the Cupping Laboratory and warehouse, and you’ve got a hometown business that adds fascinating diversity to Martin City’s already diverse business community.

“We’re happy to be here and we’re not shy about telling people our headquarters is in the Martin City neighborhood,” says Hanson, rushing off to his next conference call. “It’s Anthem Coffee Imports’ home.”